Clayco reached out to SCAD for aid in exploring new hard hat possibilities to improve worker safety. This ten week SCADPro collaboration focused on modernizing a design that is safe, lightweight, and comfortable. The full-service construction company’s plan is to manufacture these “Hard Hats of the Future.”

national publication

Read the article titled “Students Design the ‘Hard Hat of the Future’” by Builder about taking our designs into production.

Article on Clayco’s website.

Prototypes by SCADPro Team Media/Photography by SCAD Creative Direction

Understanding the Client

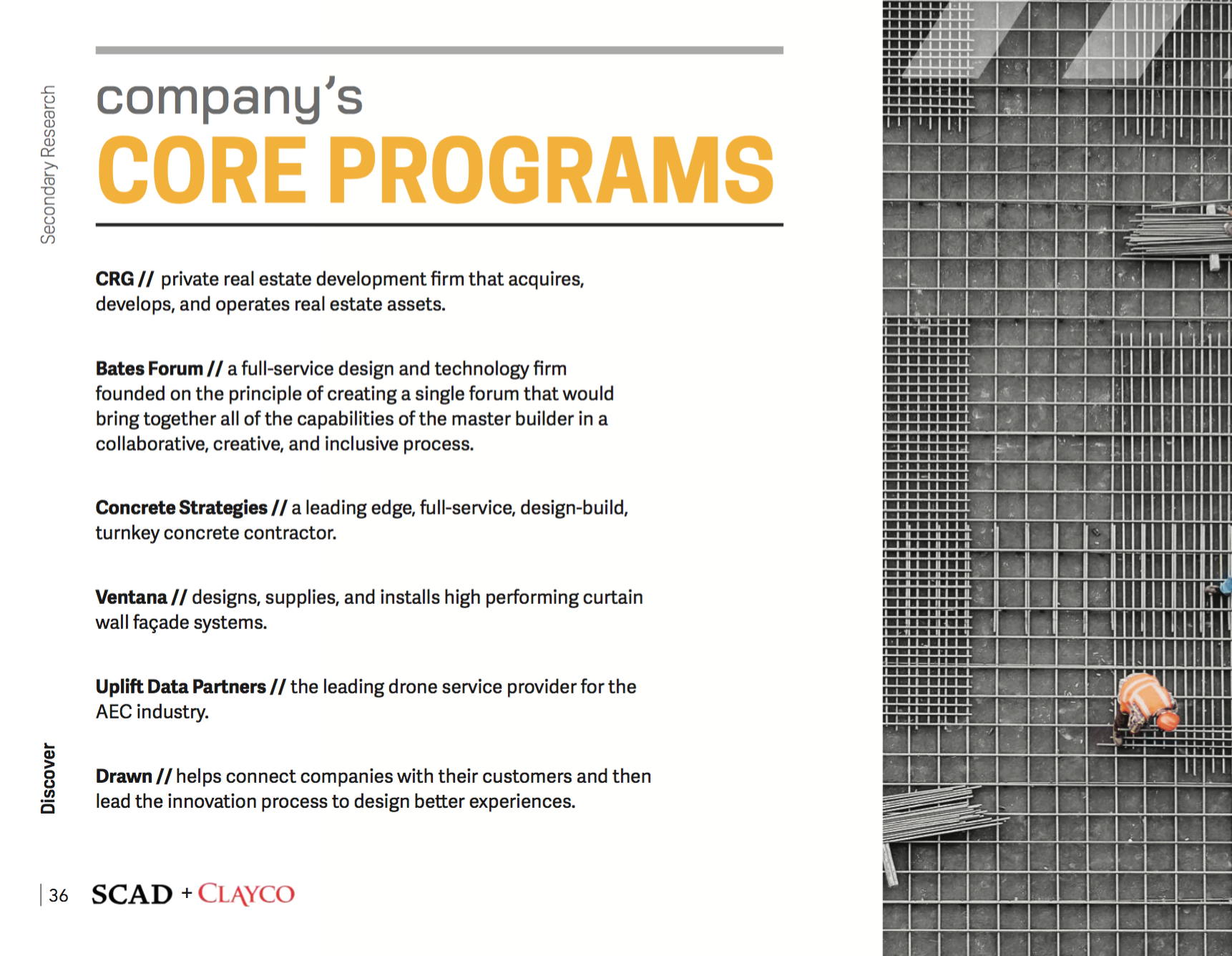

Clayco is a full-service, turnkey real estate, architecture, engineering, design-build, and construction firm that delivers clients around the world the highest quality solutions on time, on budget and above and beyond expectations. Every project they’ve built has been fully integrated and has revolutionized the design-build process every step of the way. Their building process delivers solutions of the highest standard, and clients have trusted Clayco to handle their most complex construction projects for over 30 years.

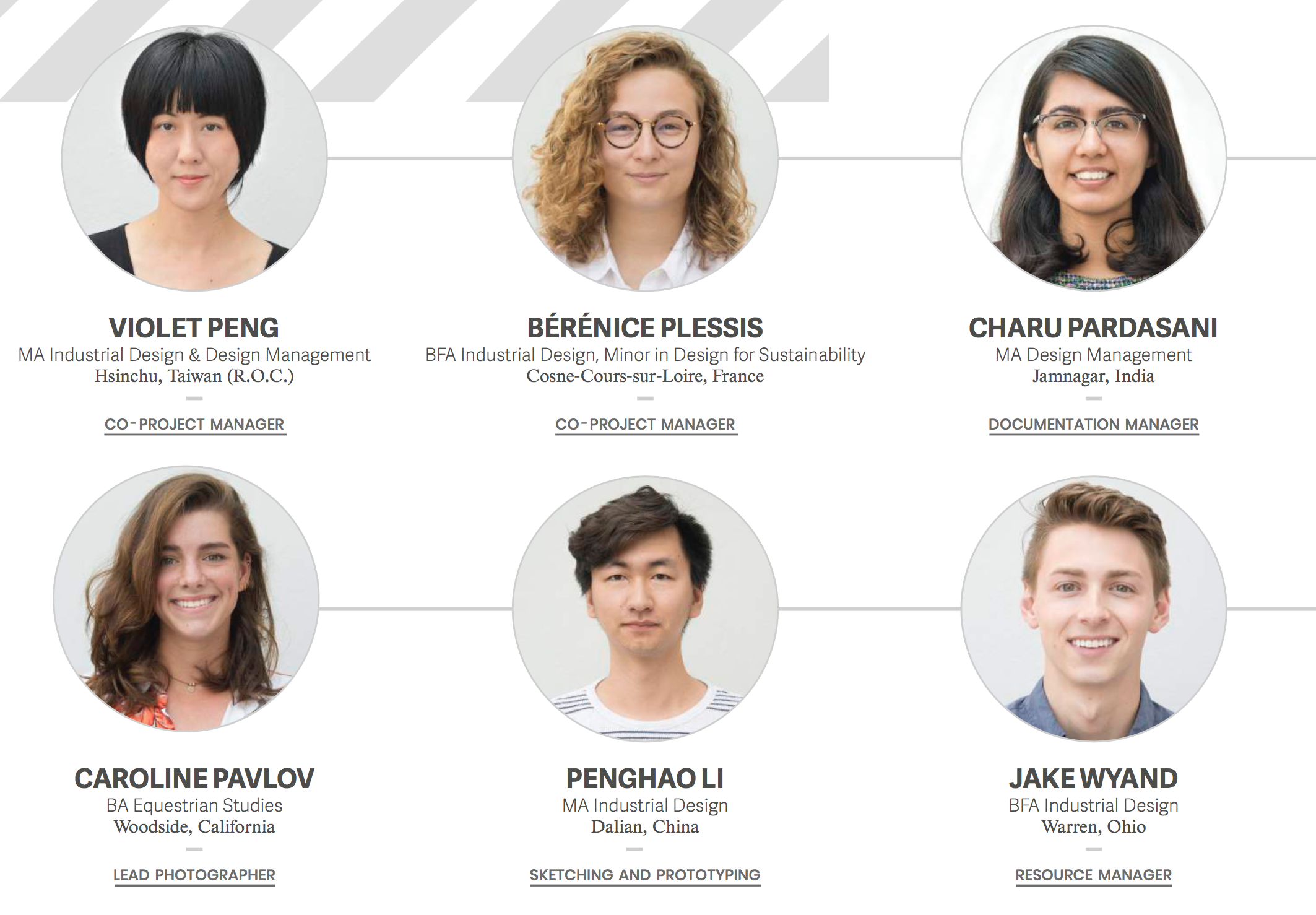

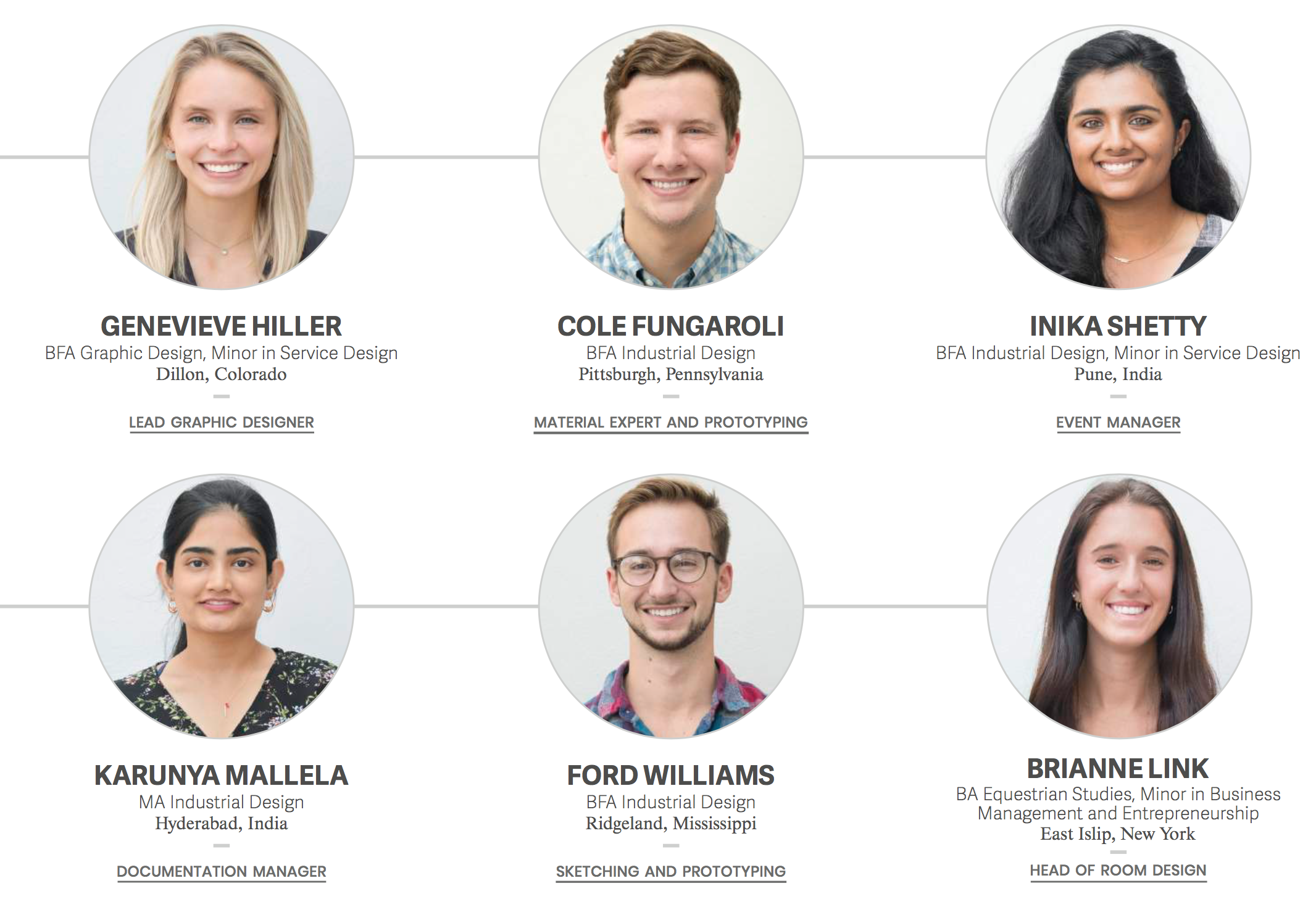

Meet the team

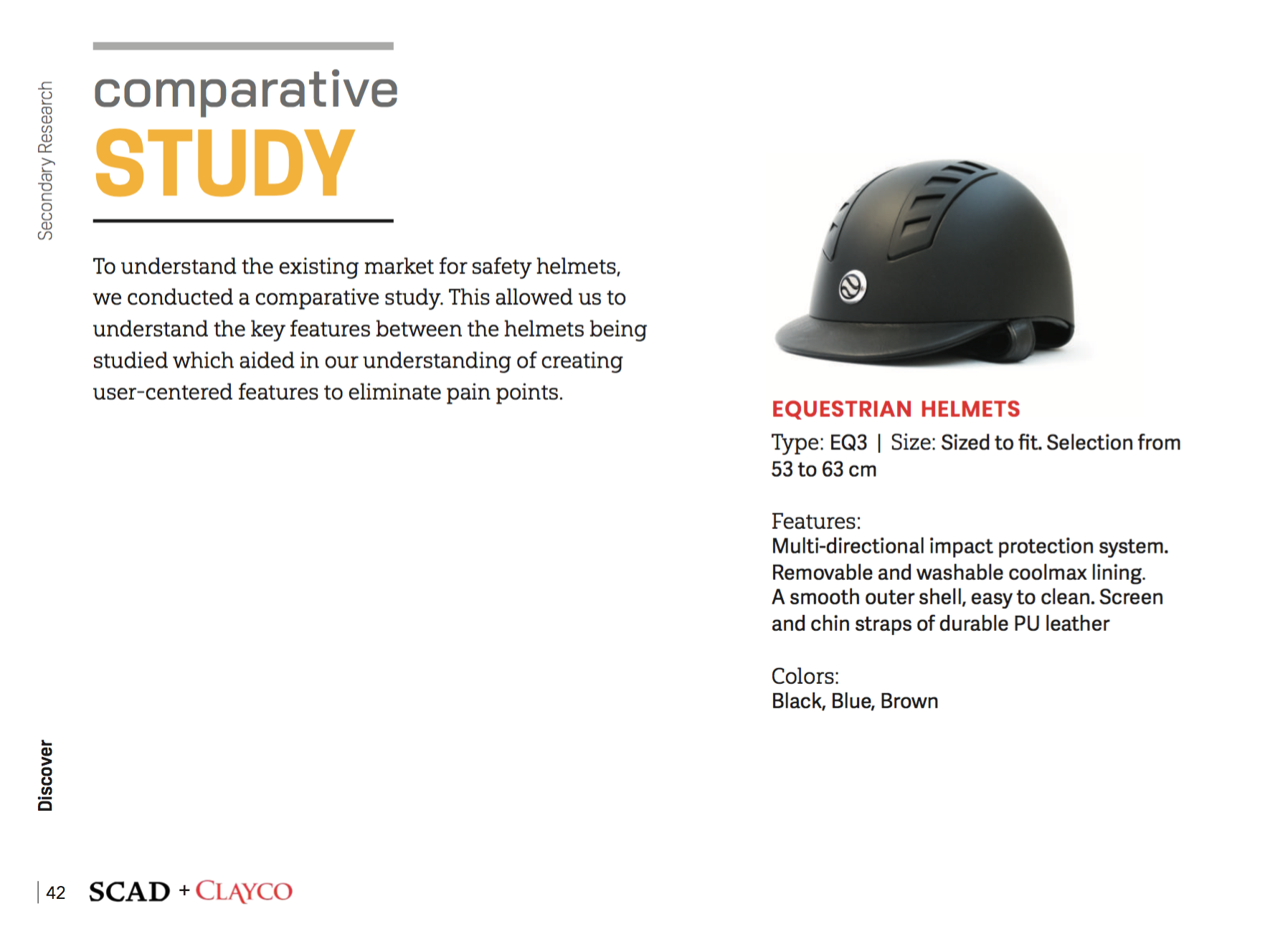

The Clayco SCADPro design team is a combination of students from five different countries studying a variety of four different majors and minors. Within the team, the students’ major studies include Design Management, Equestrian Study, Graphic Design, and Industrial Design. The diversity and skill set variety of our team allowed us to derive multiple design approaches to invent original, complex, and cutting-edge ideas.

Mission Statement:

Our mission is to design a sustainable and durable hard hat to make the lives of construction workers safer and more comfortable.

Secondary Research

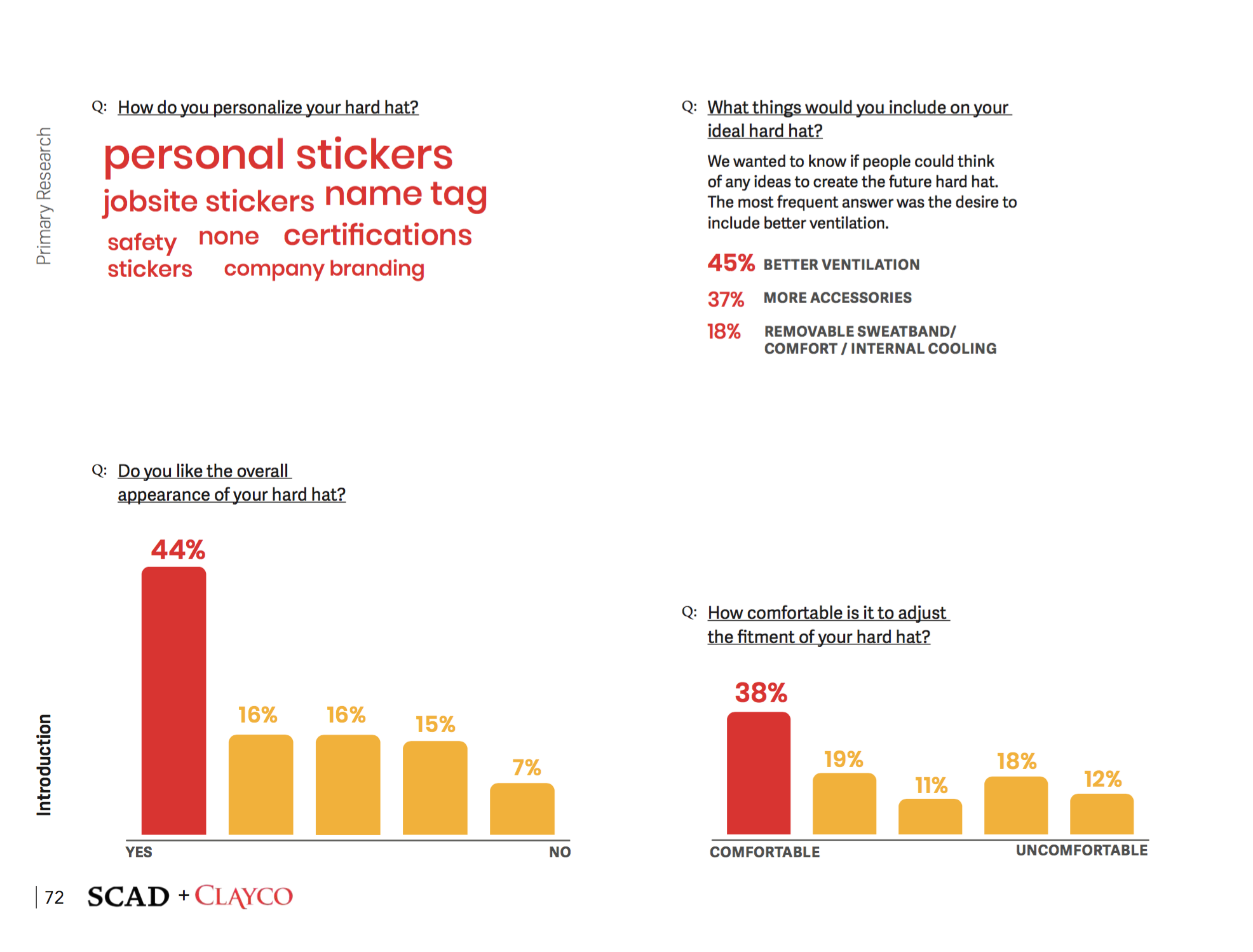

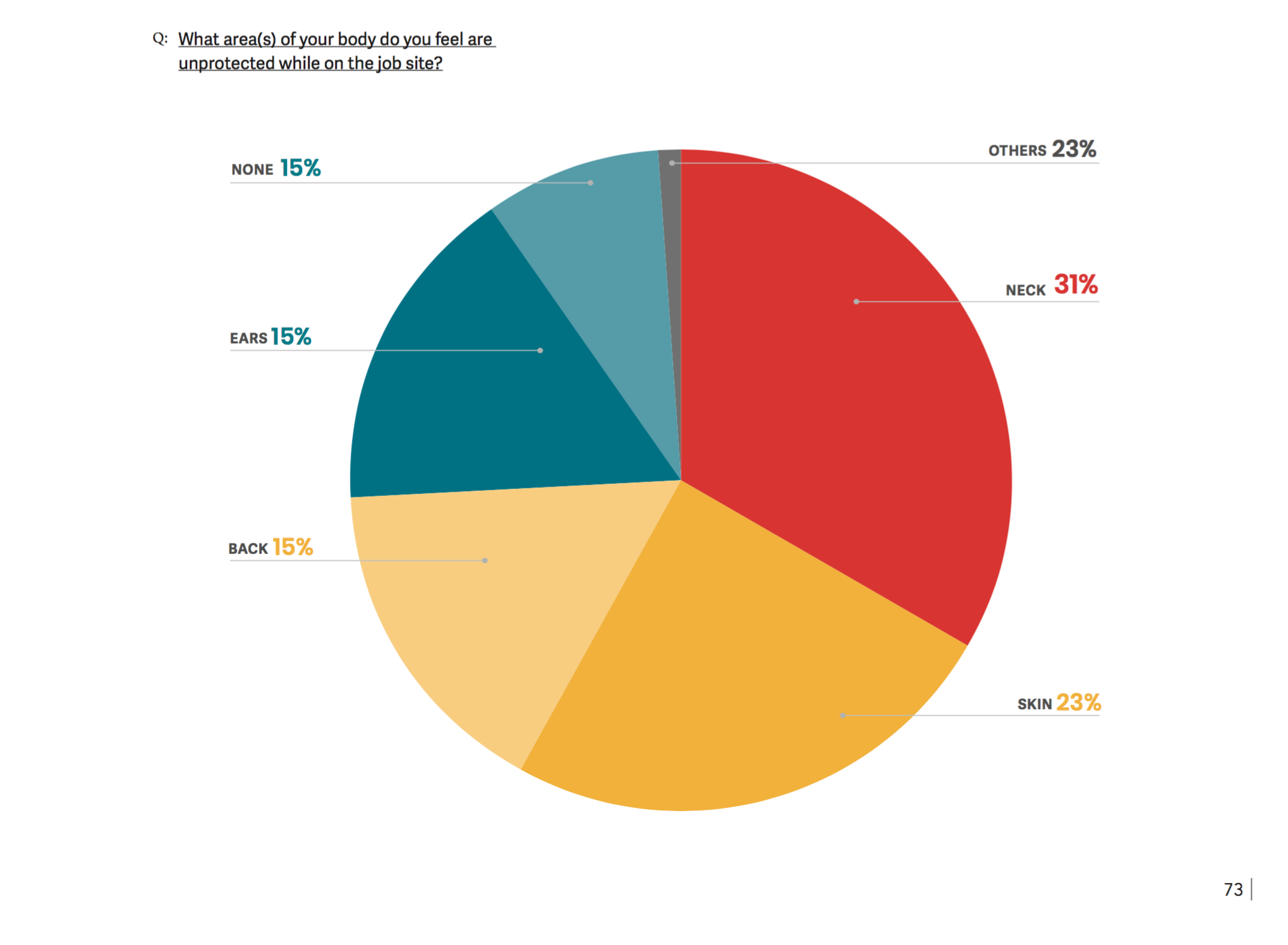

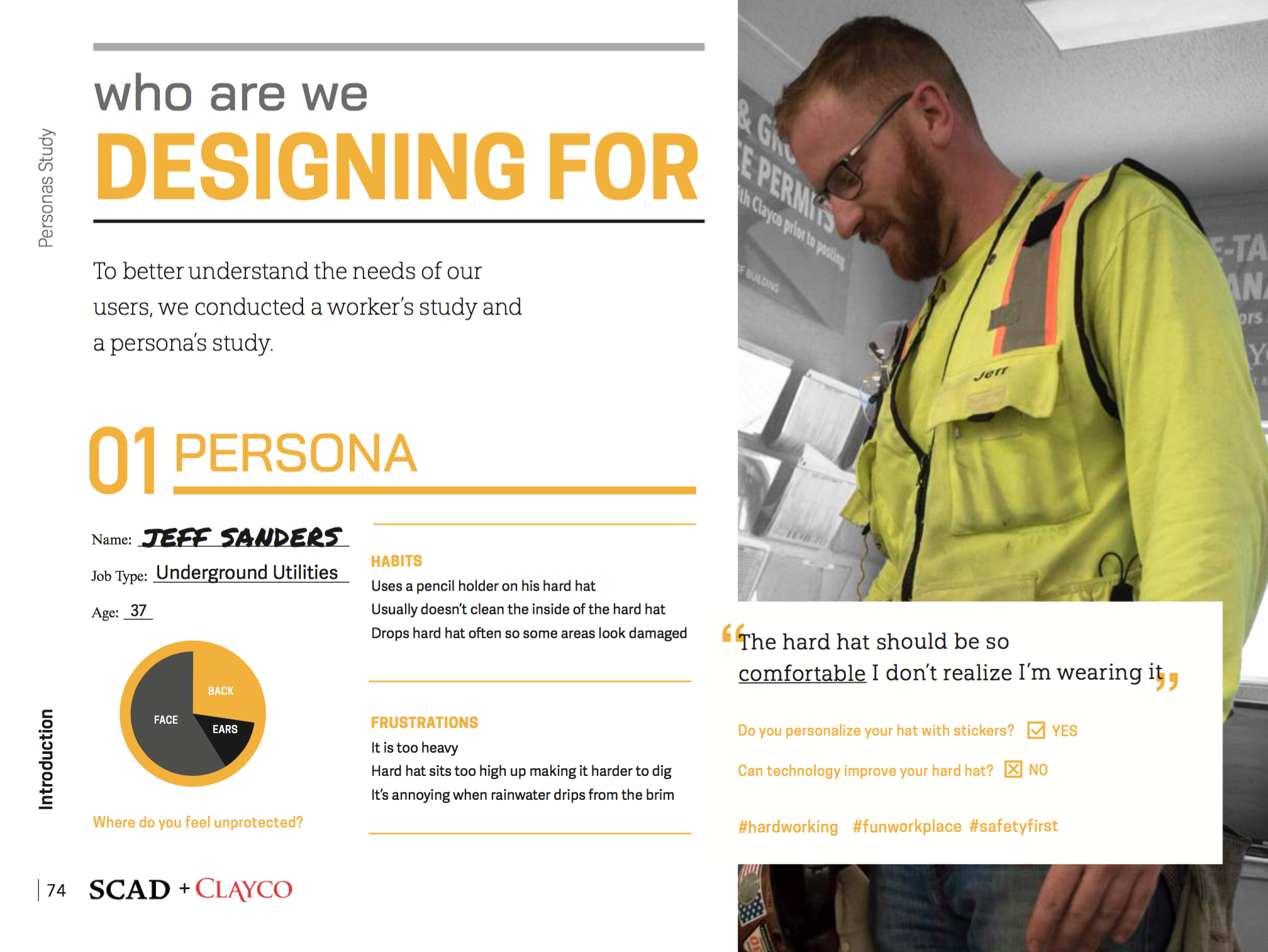

PRIMARy research

Prototyping

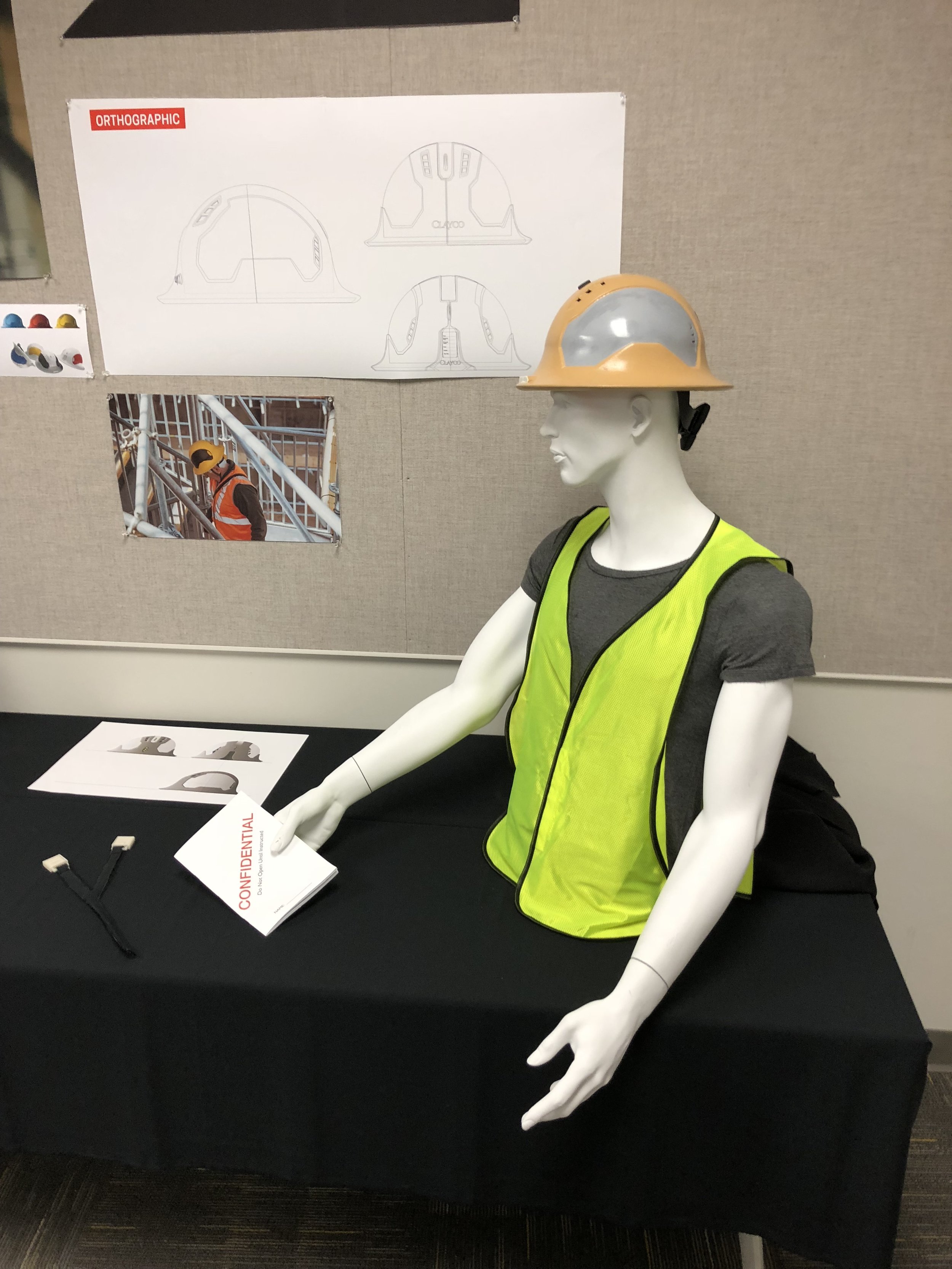

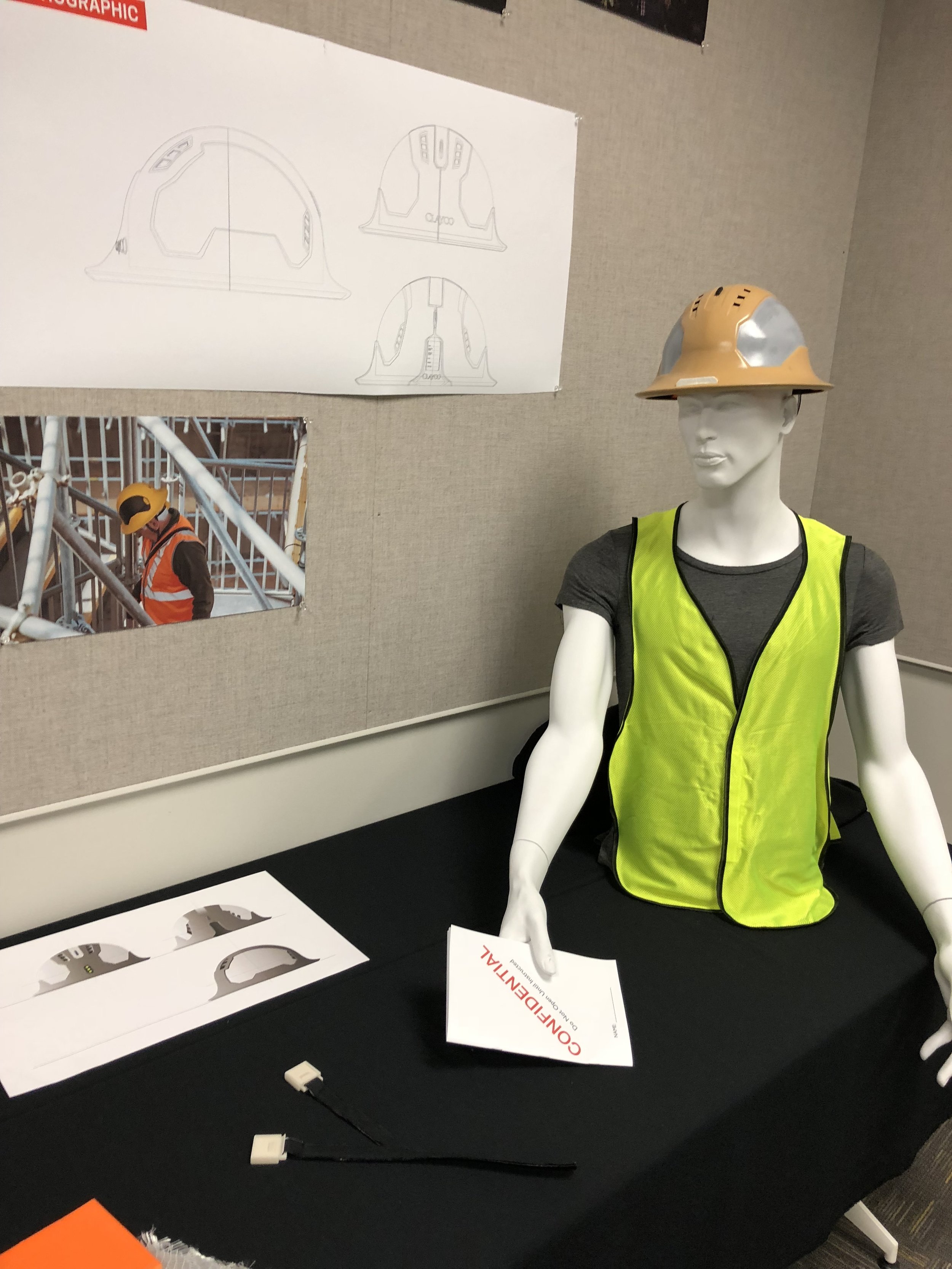

Our rapid prototyping process included 3D printing, carving high density foam, and painting.

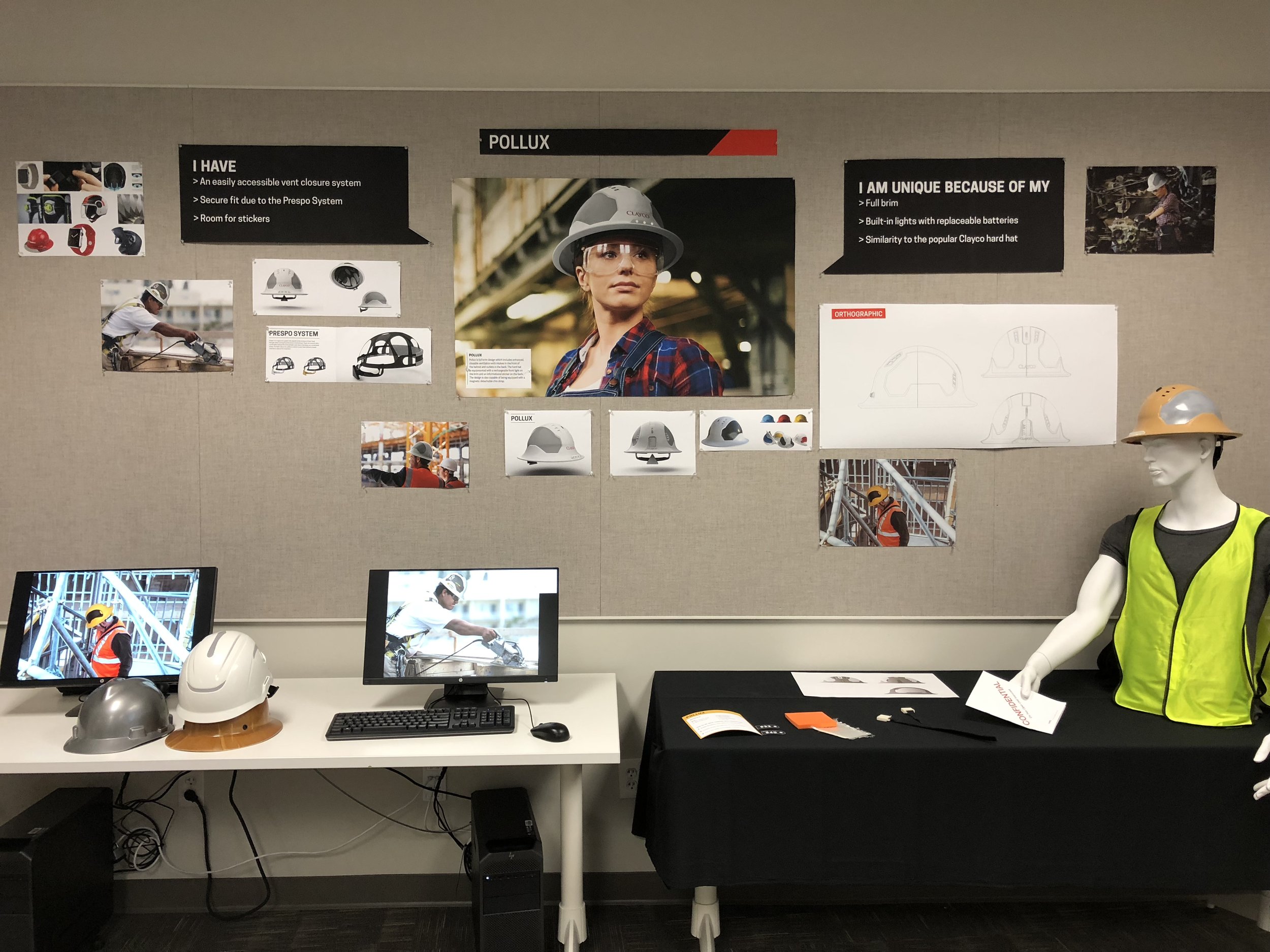

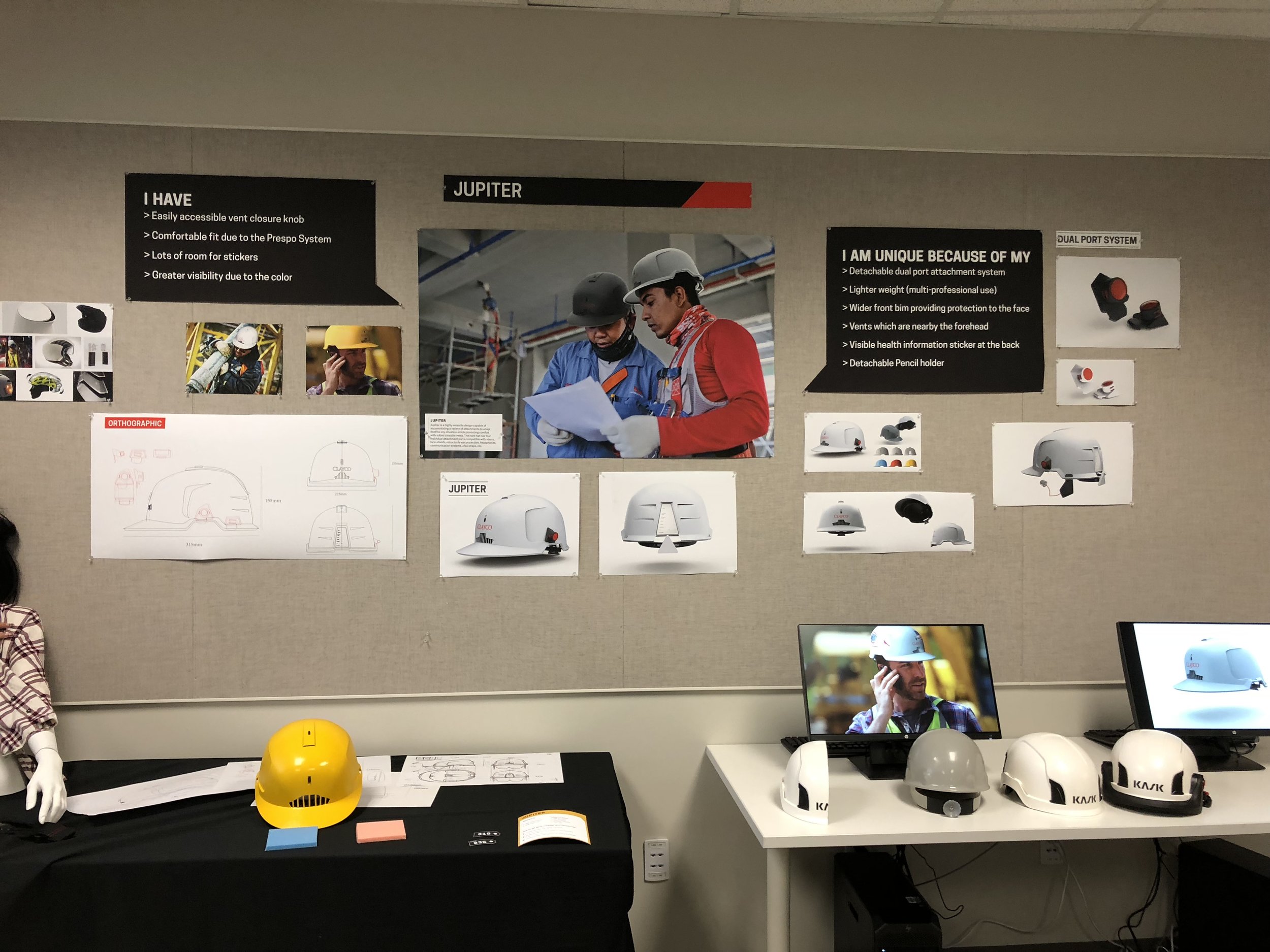

Final presentation

Products

My Role

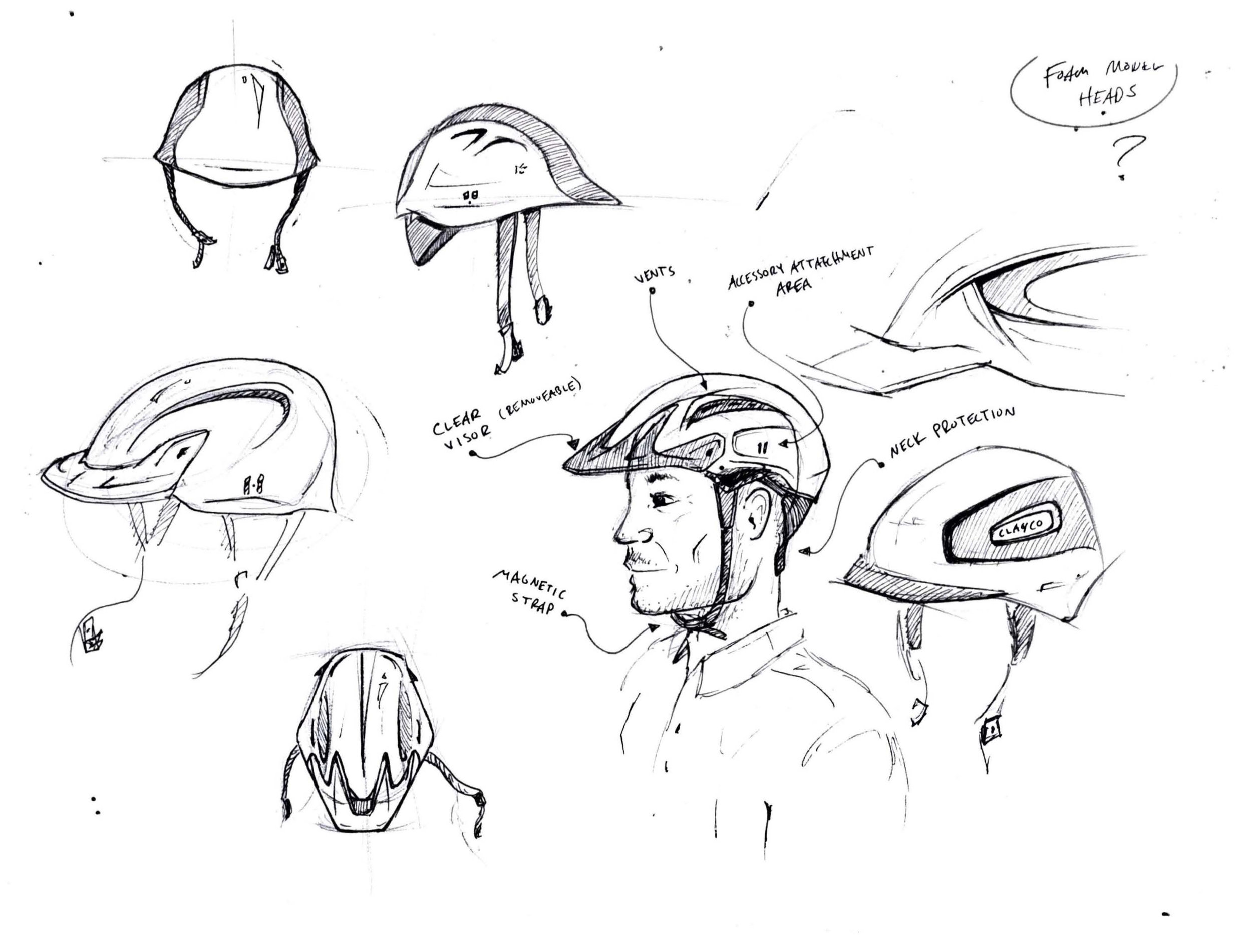

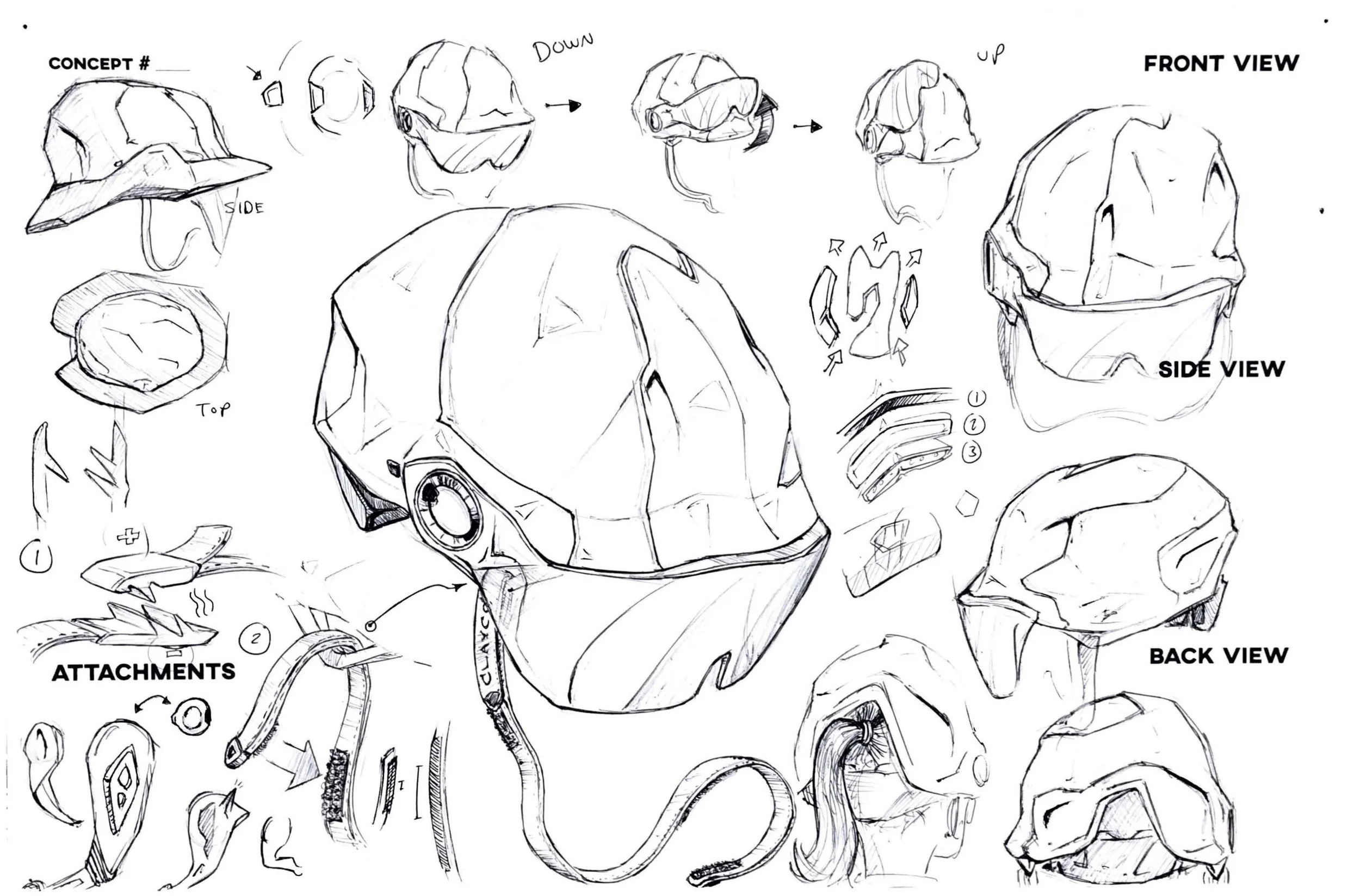

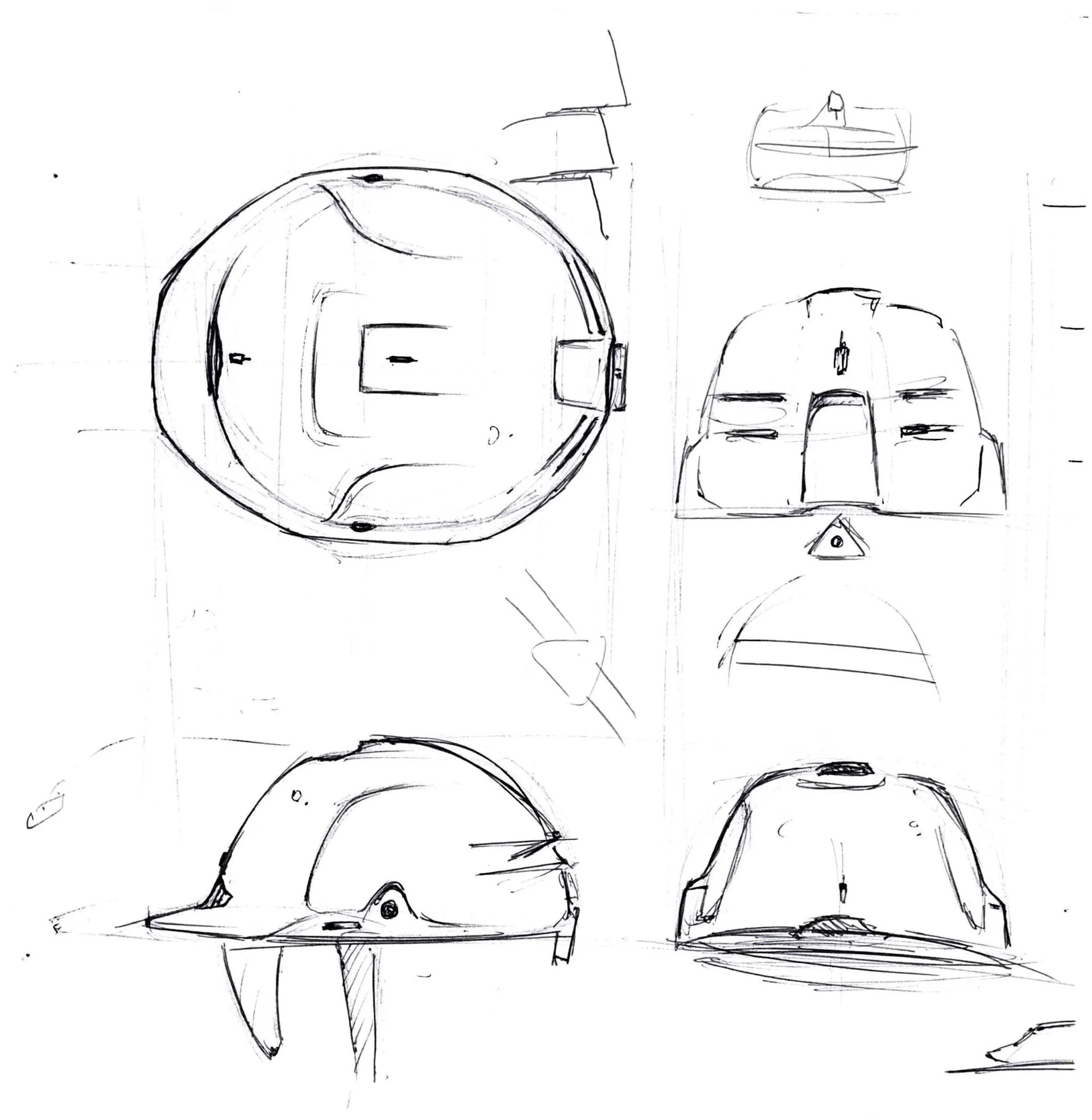

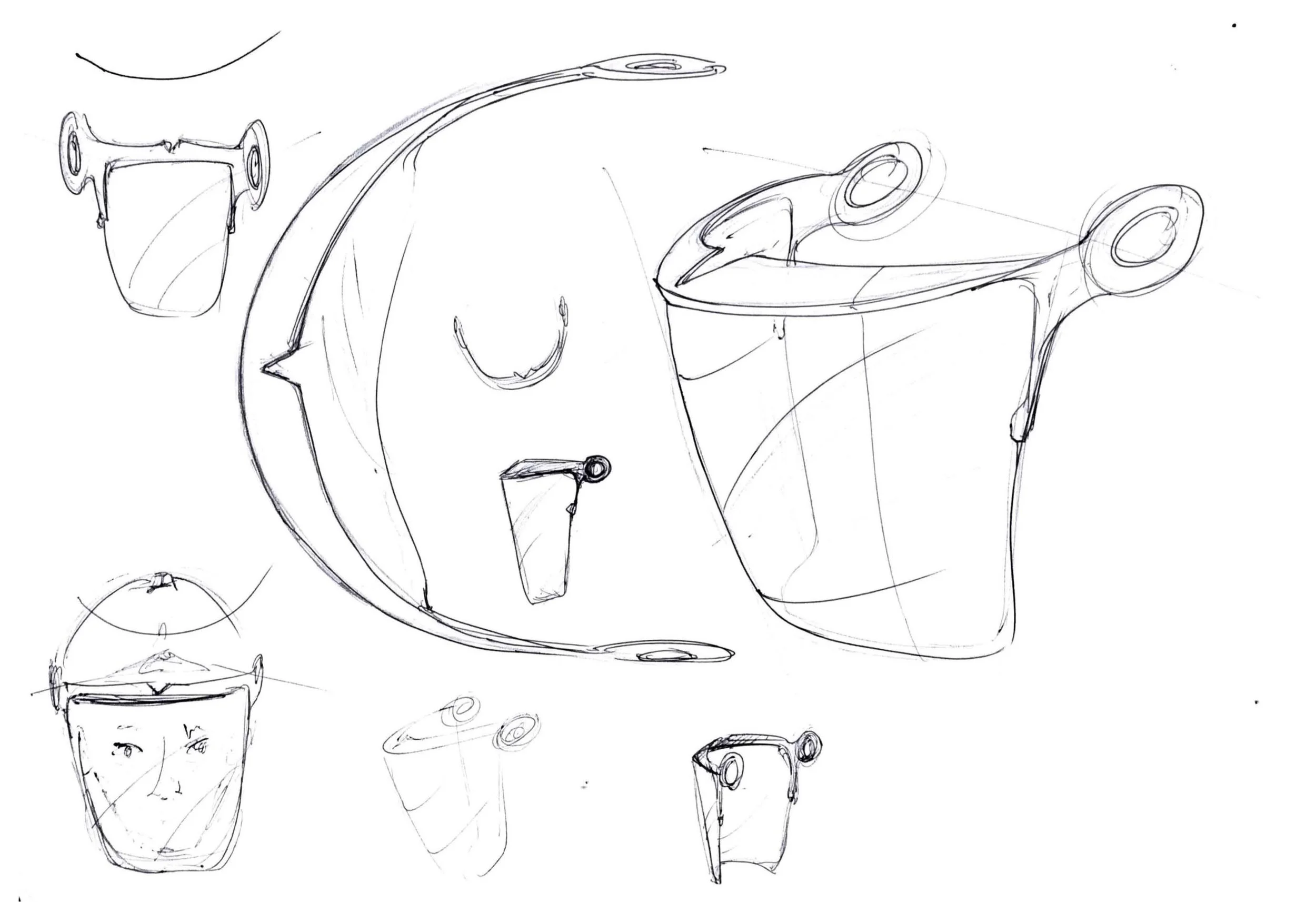

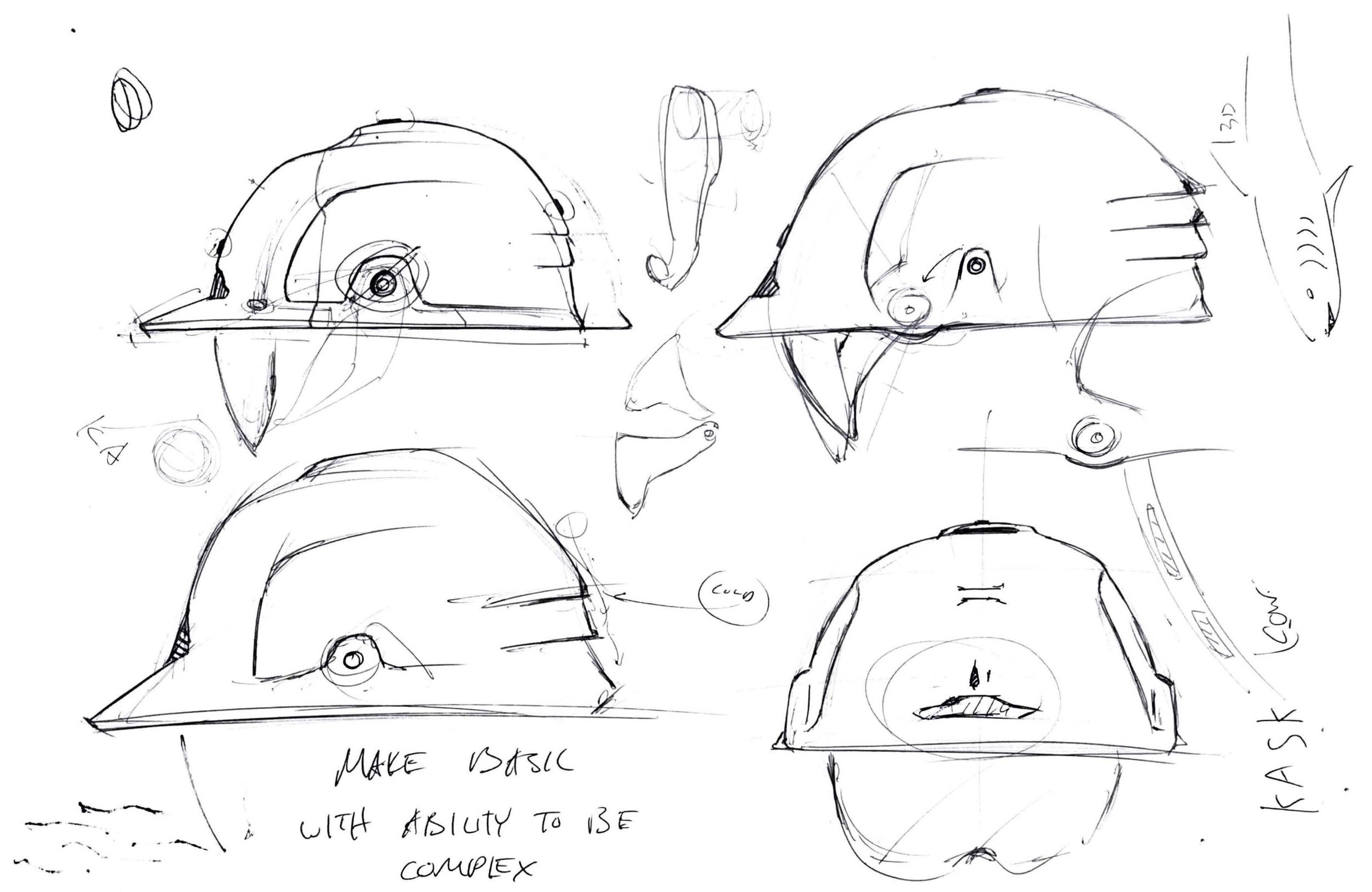

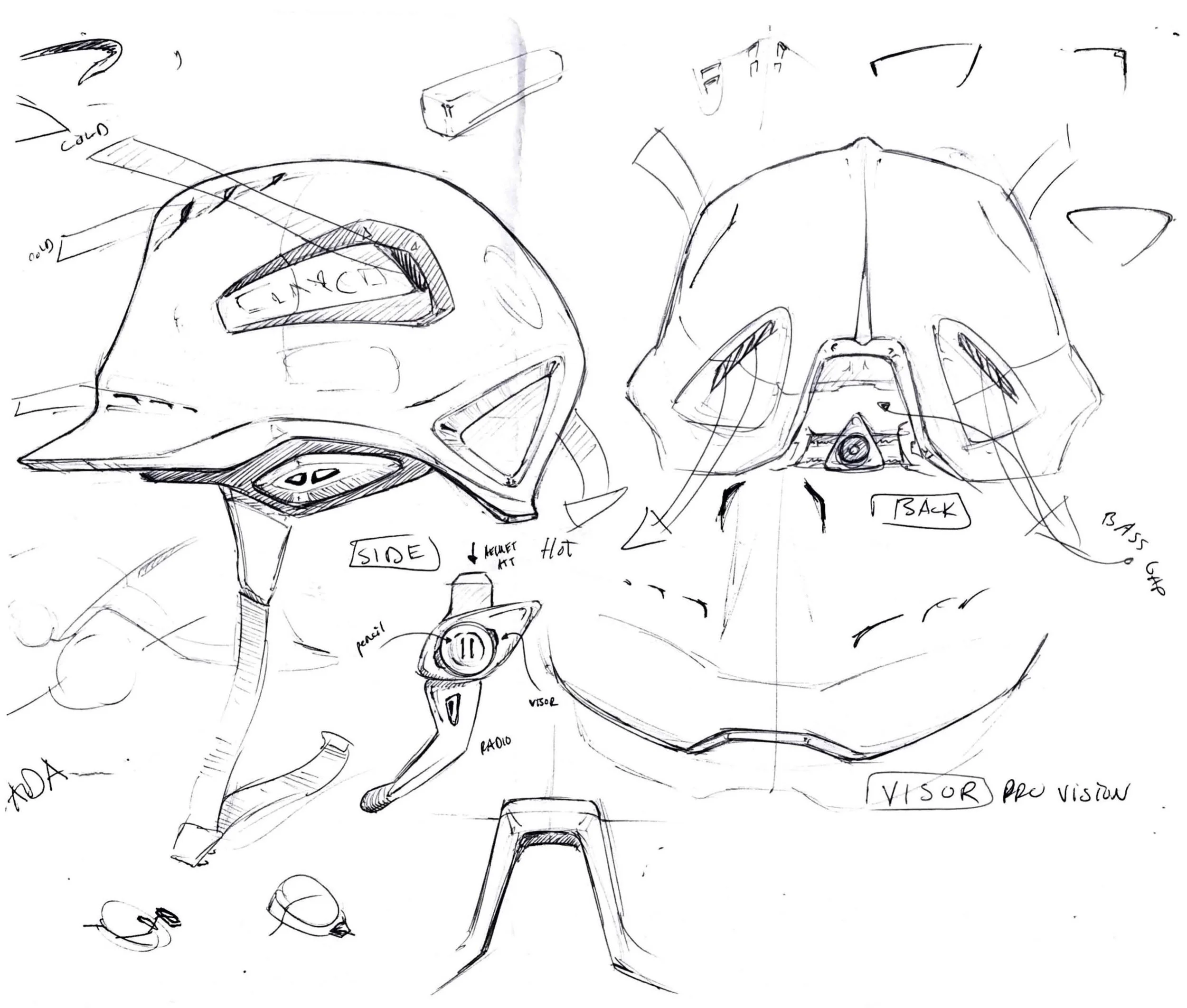

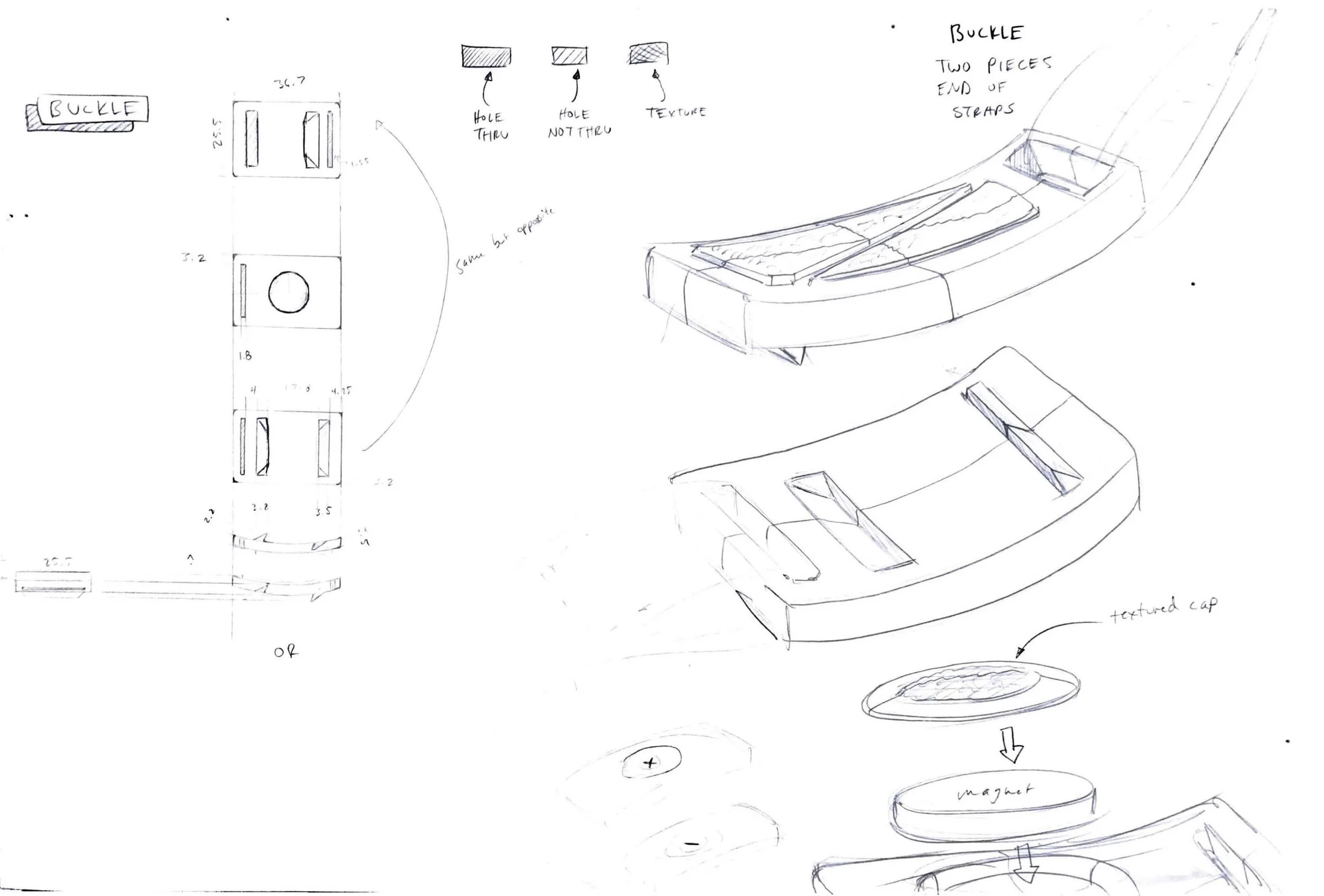

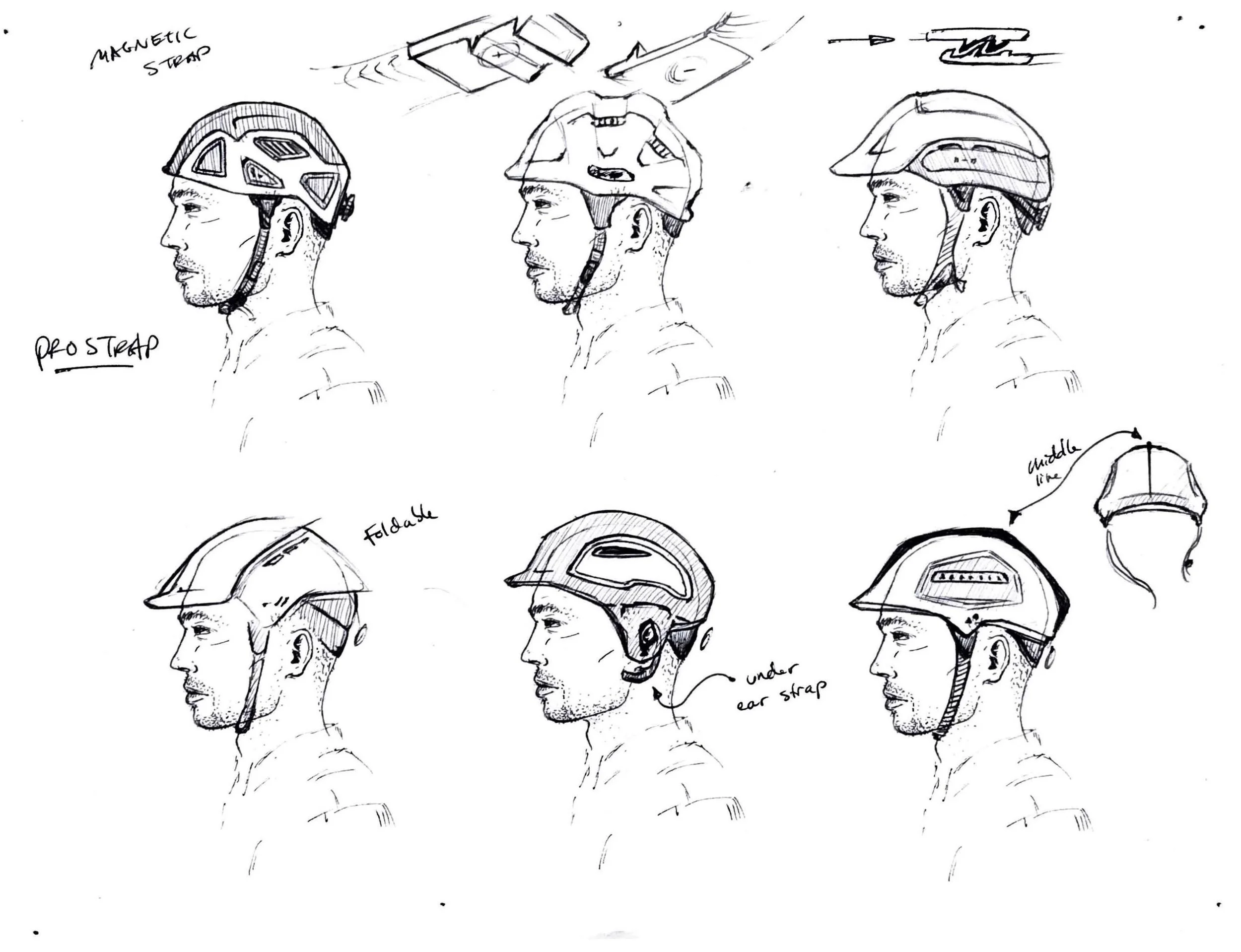

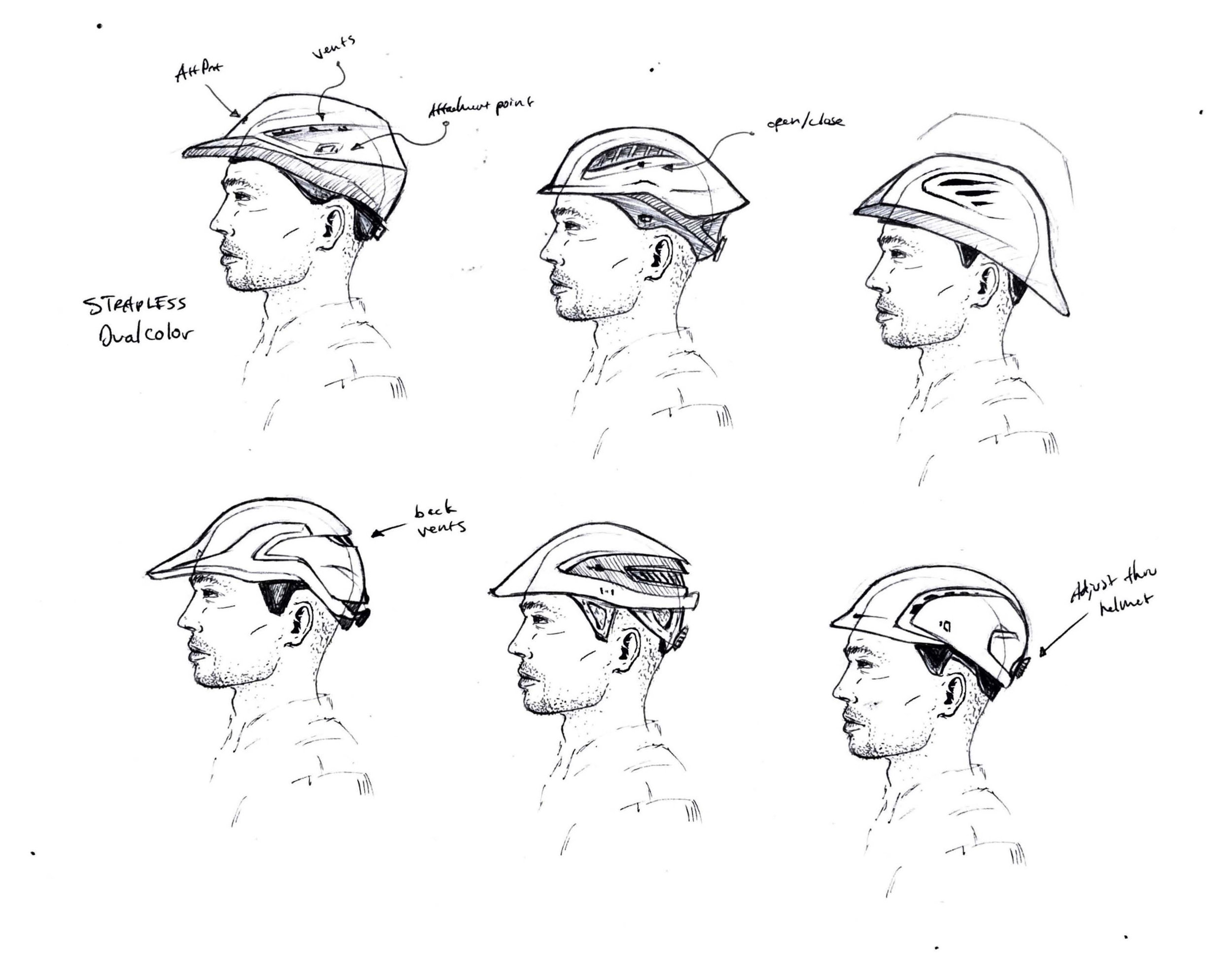

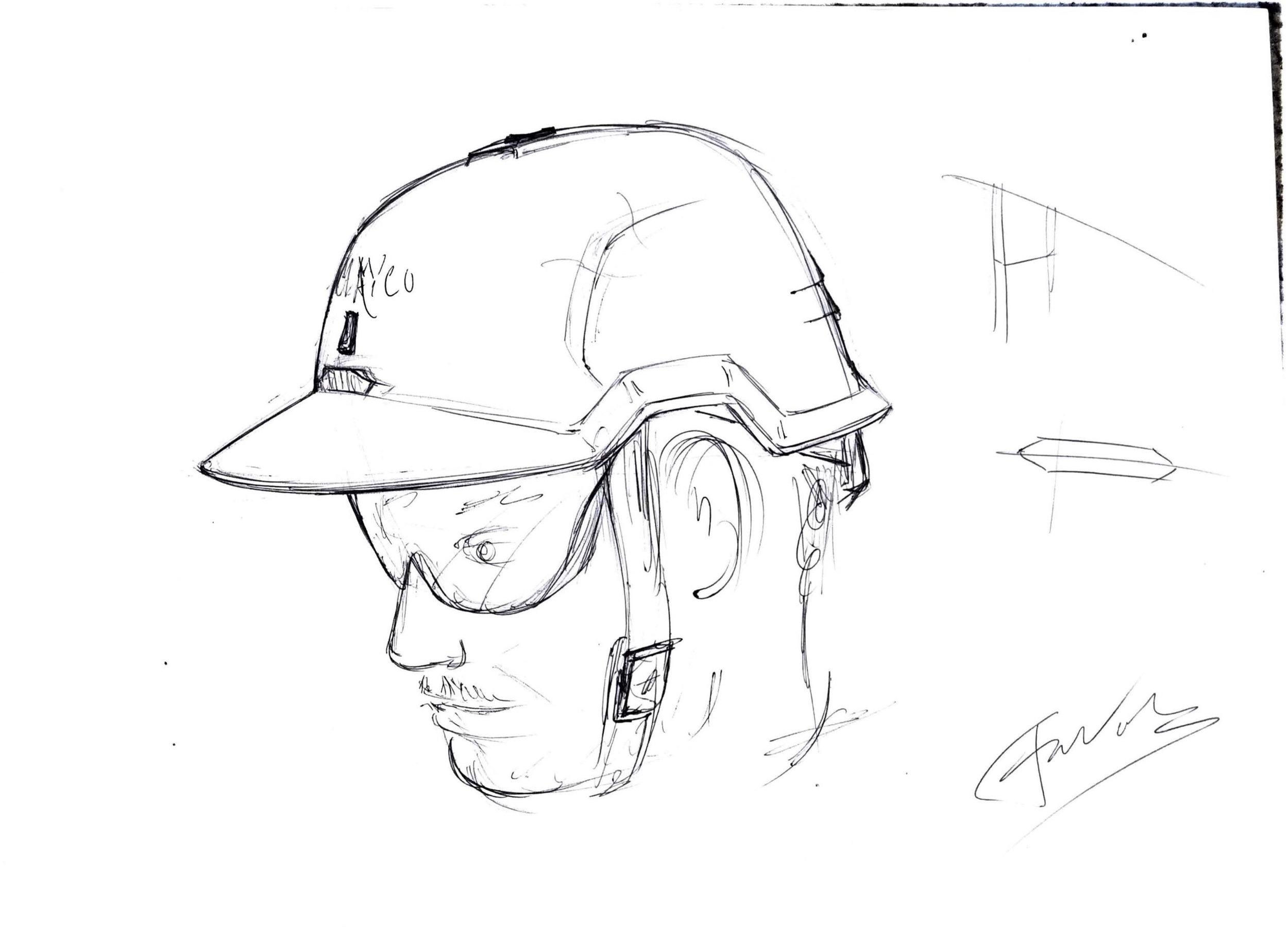

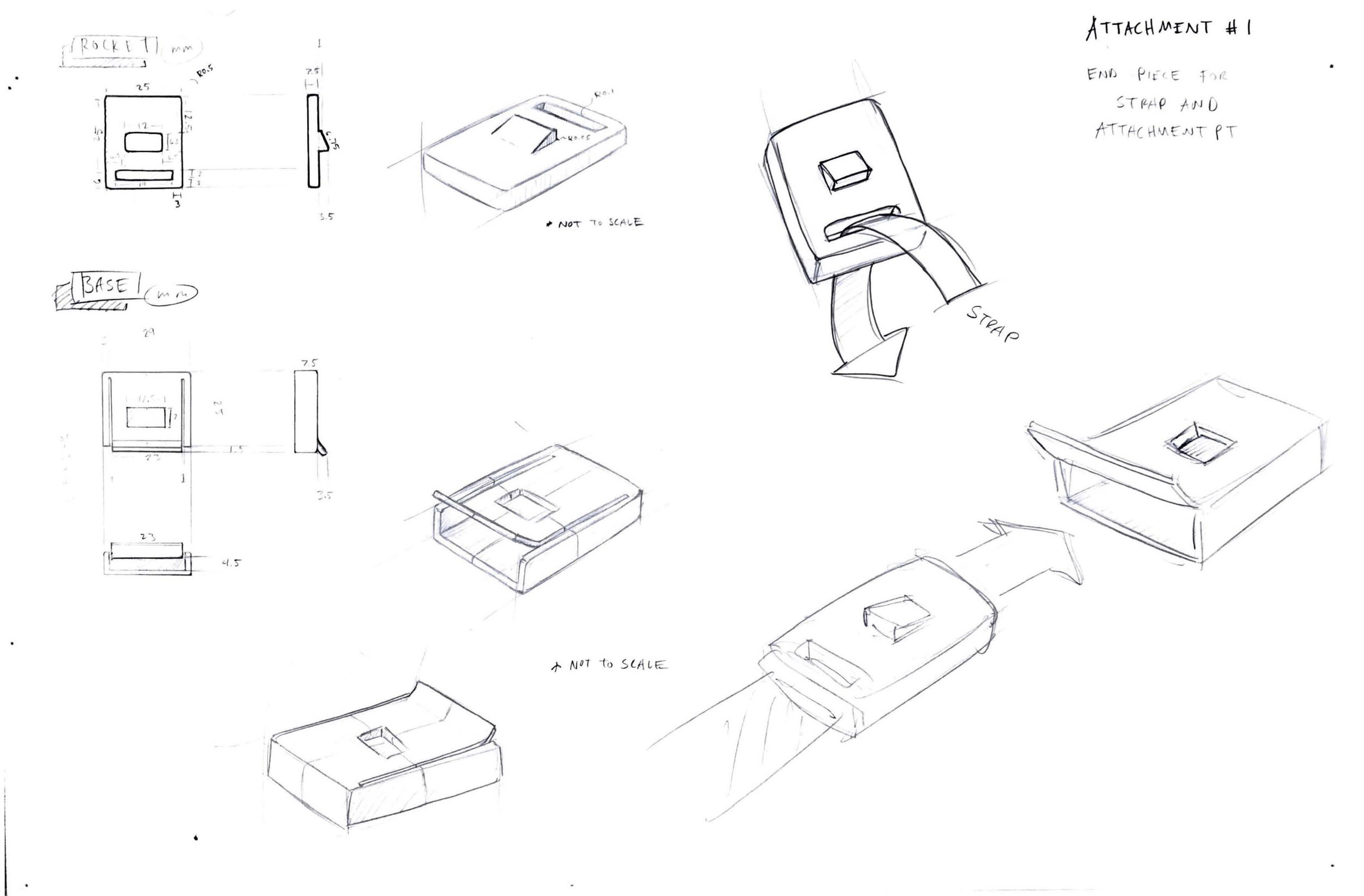

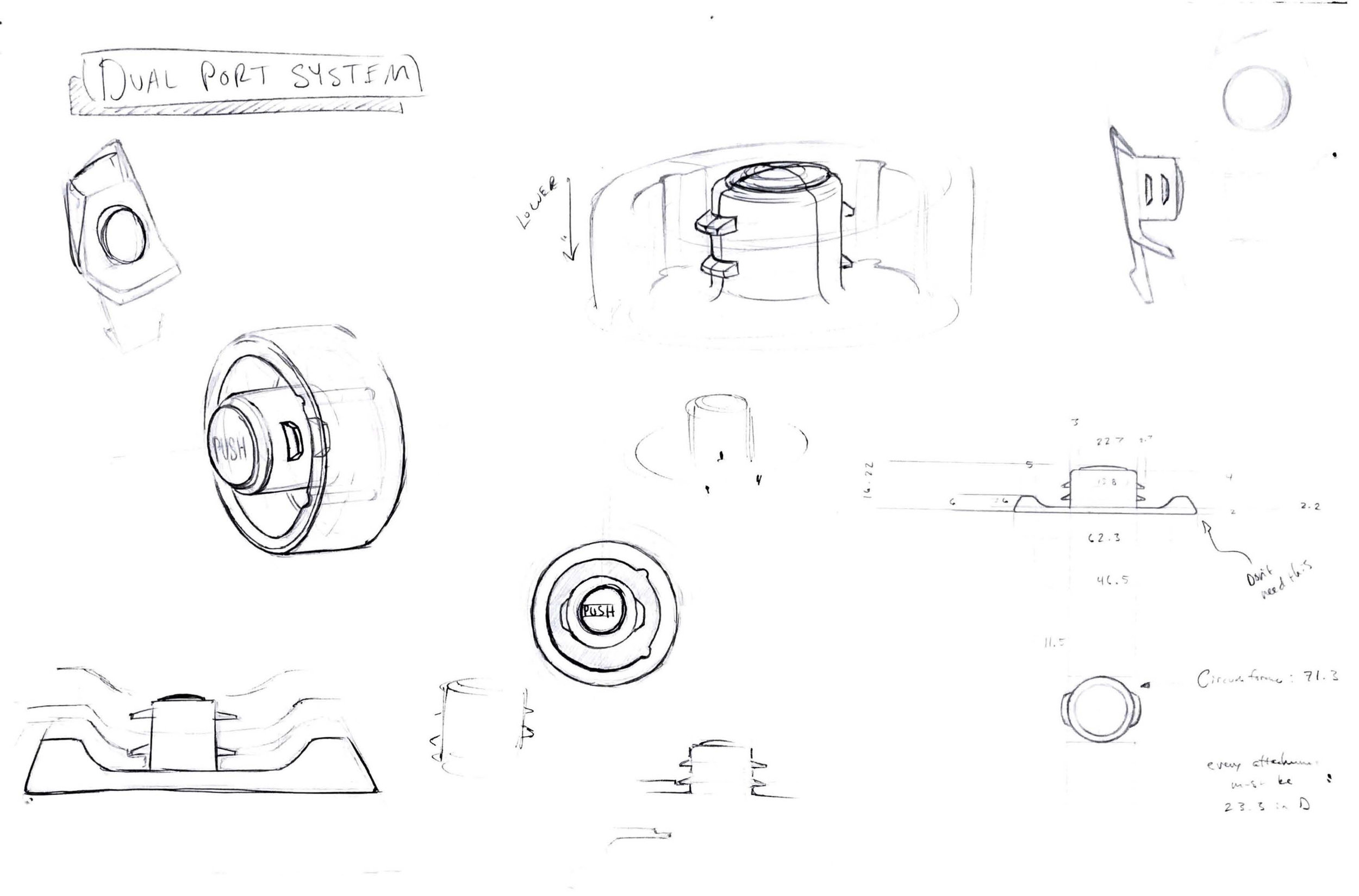

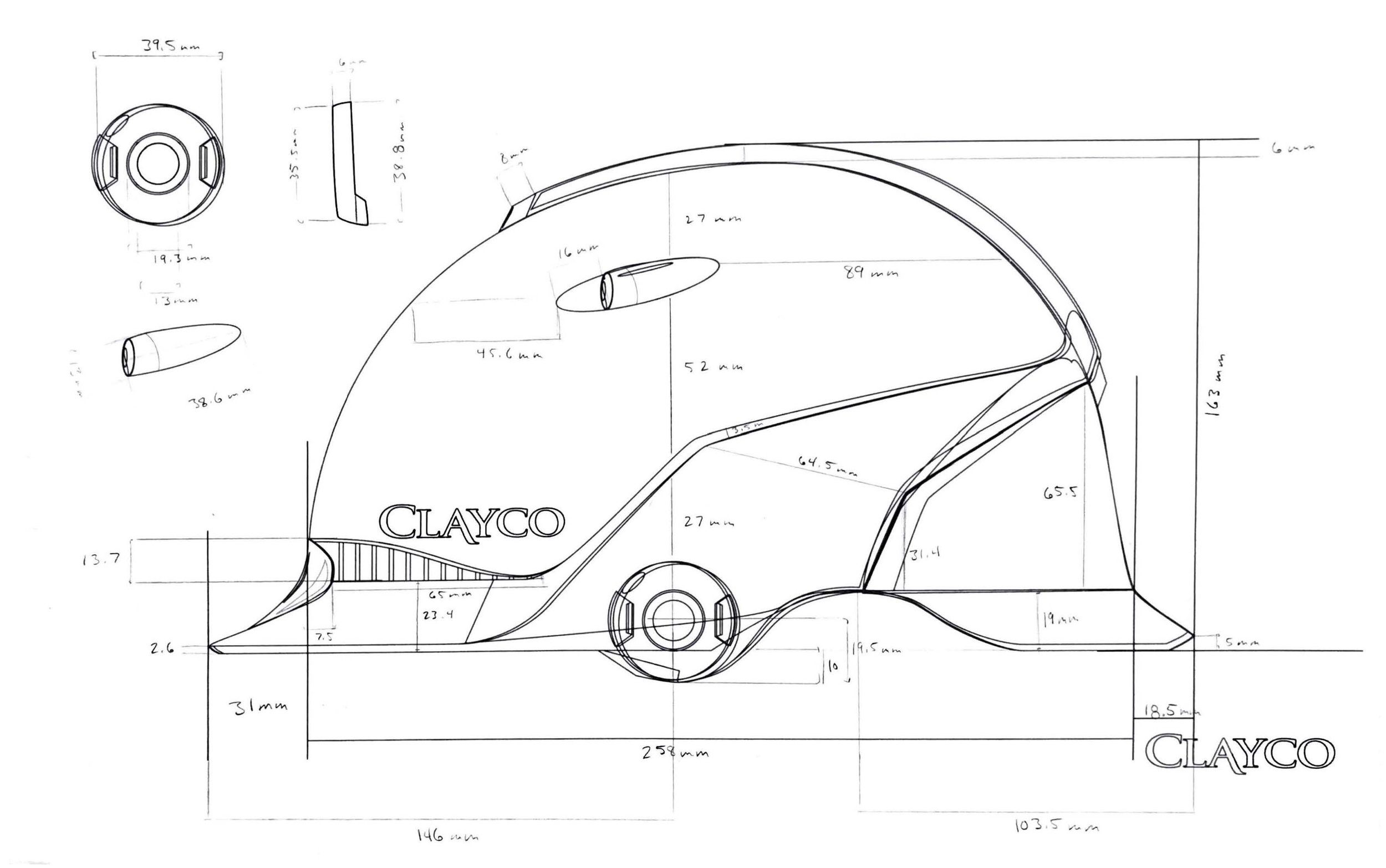

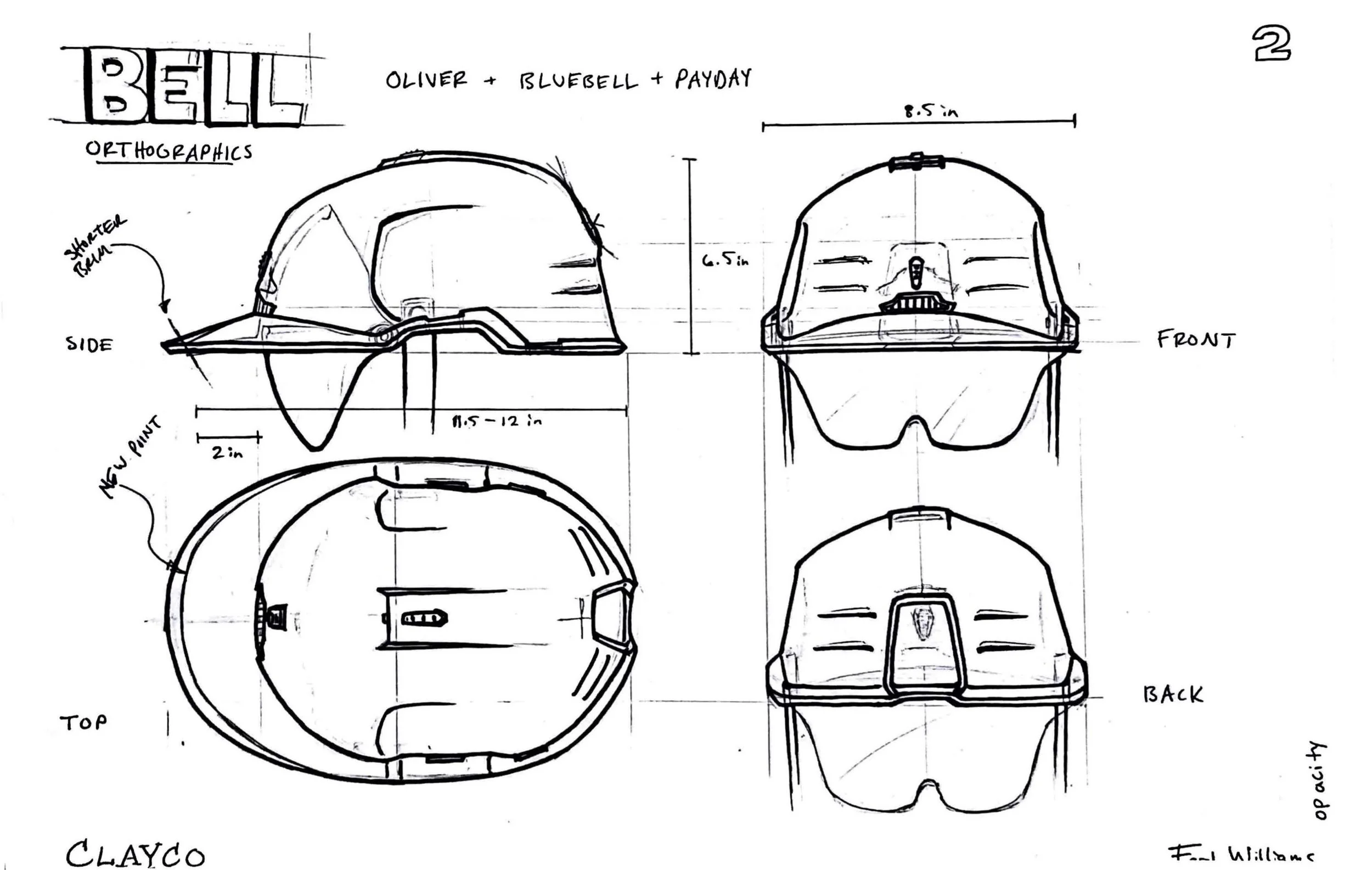

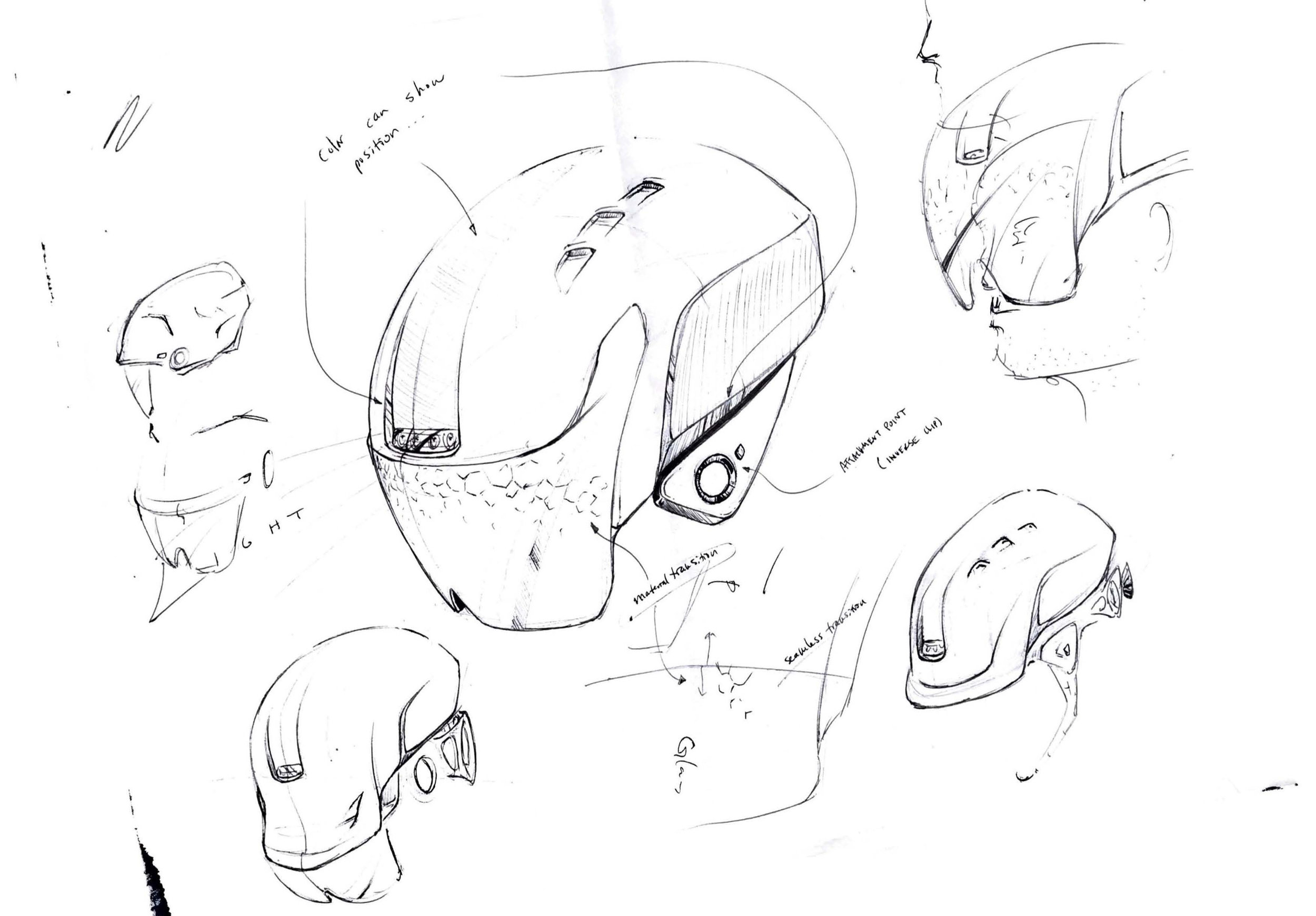

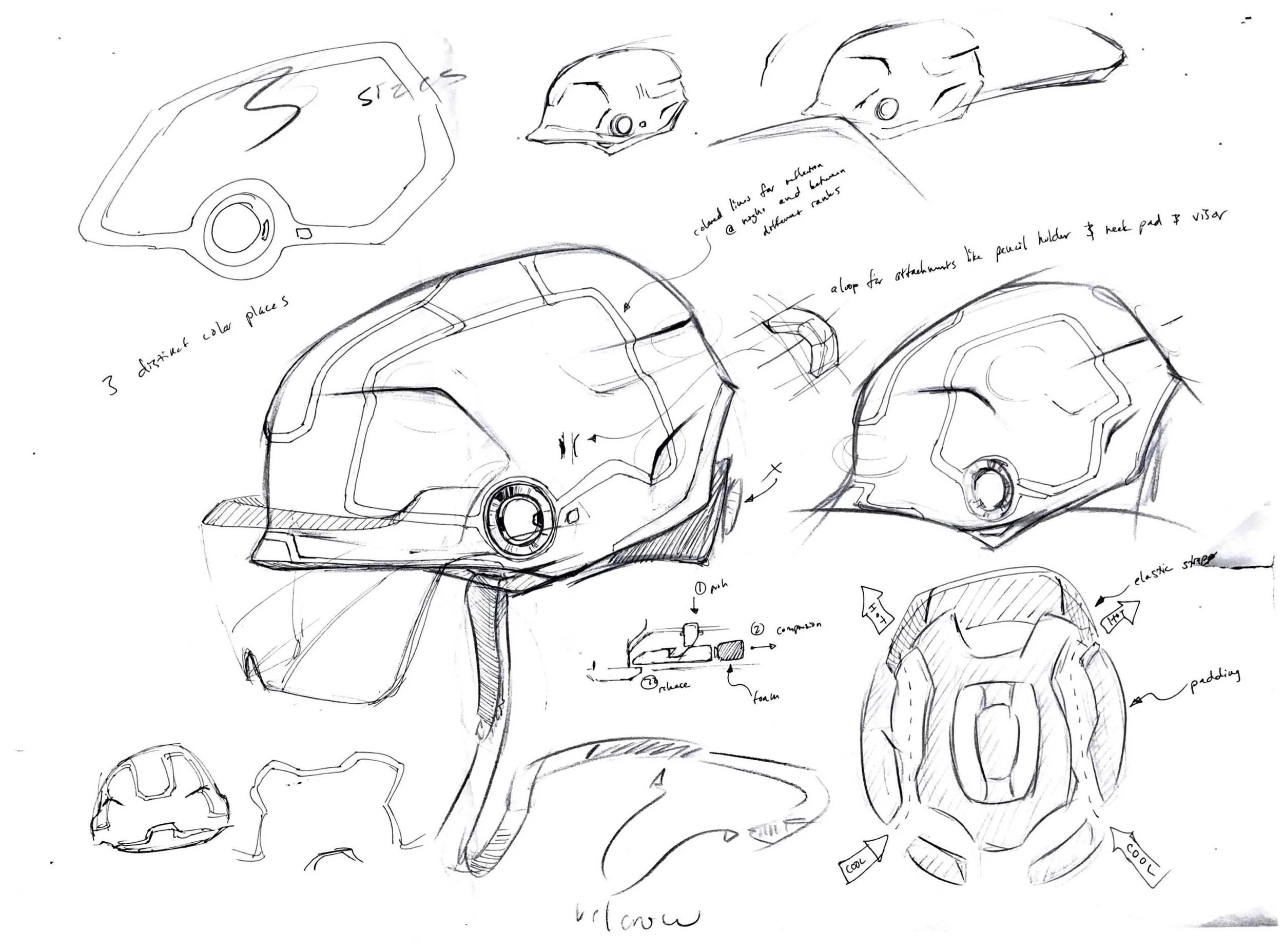

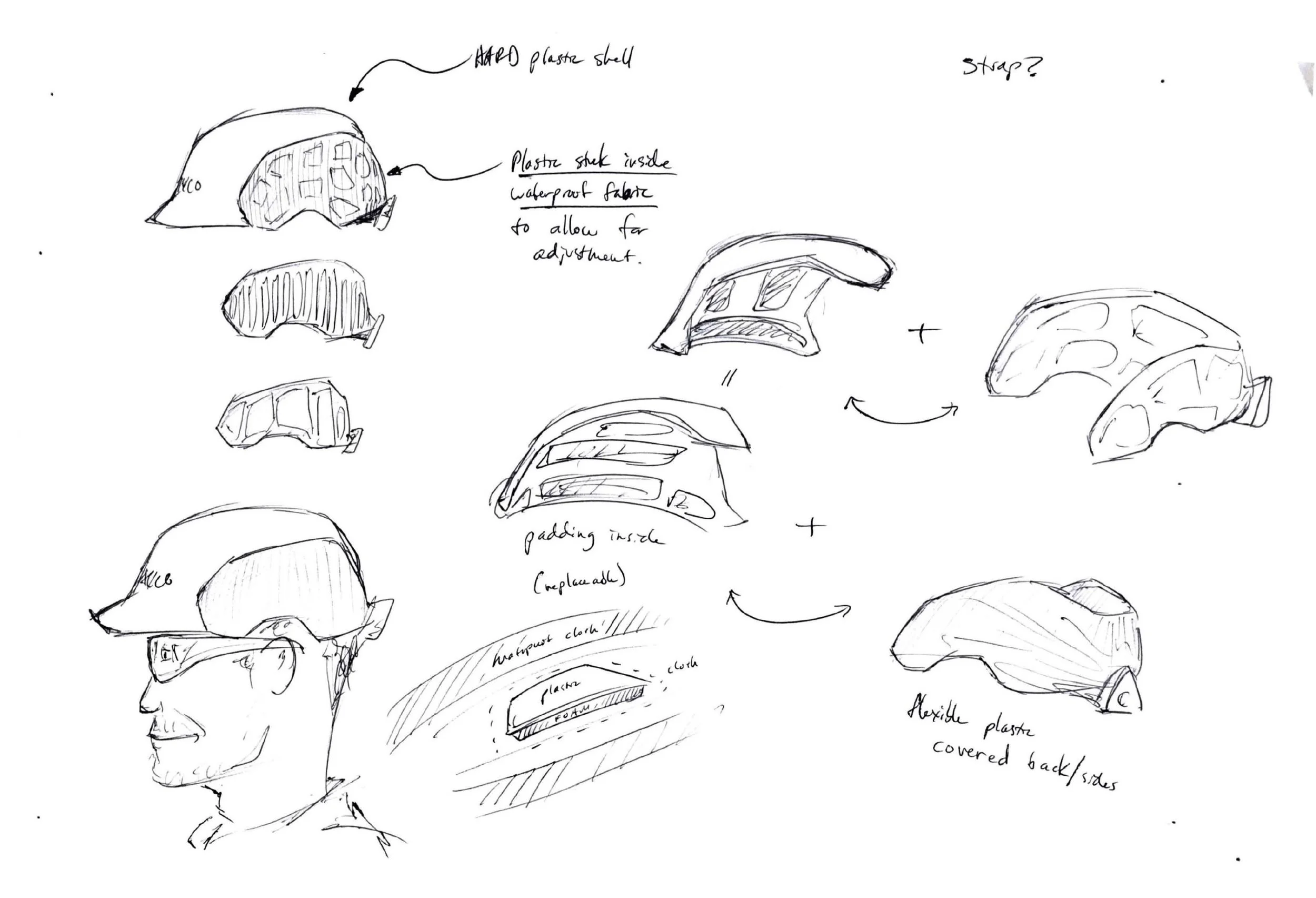

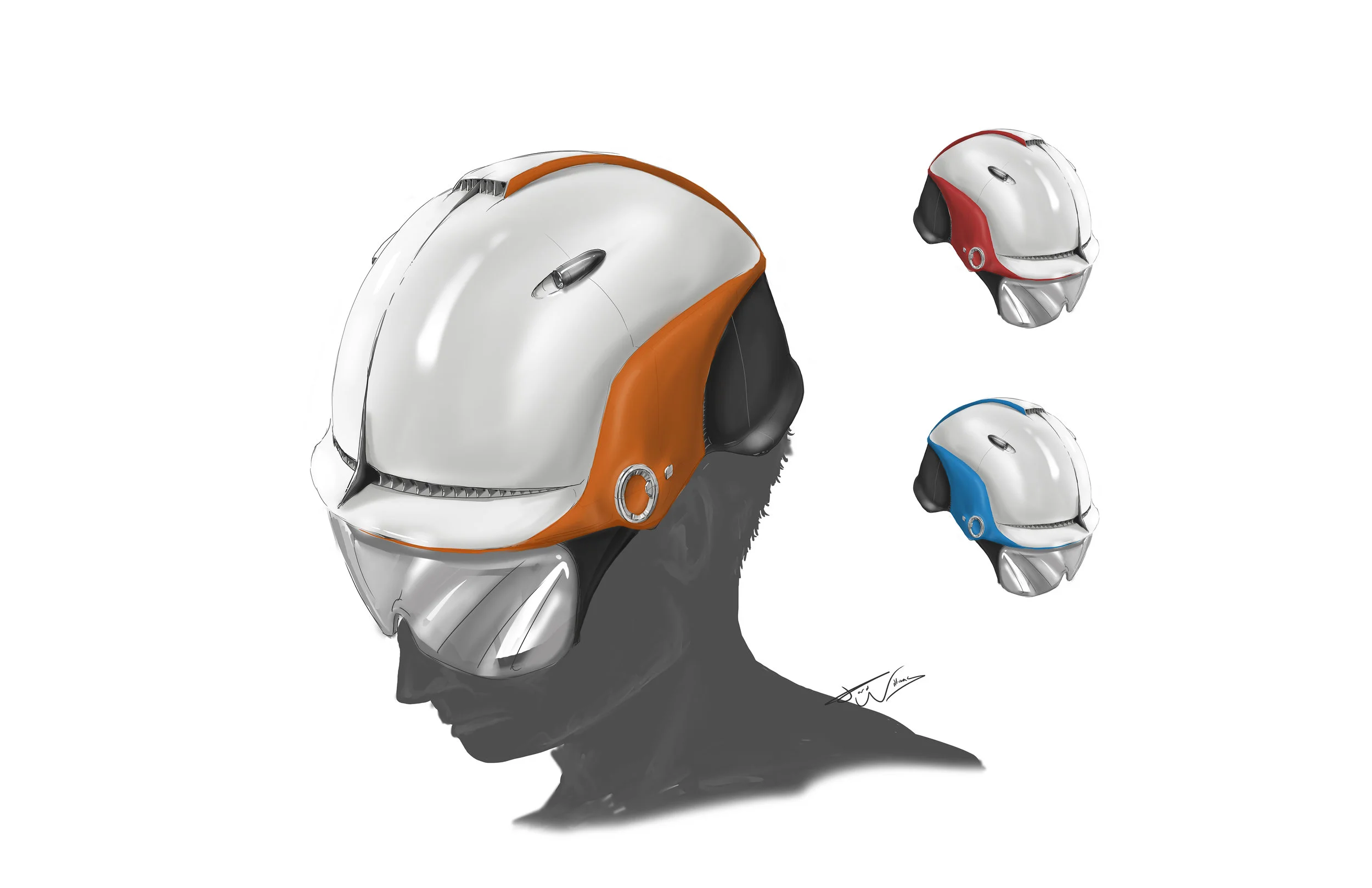

I was the Lead Design Sketcher on this entire project and helped on a majority of the prototyping phase. Being the Lead Design Sketcher I directed the ideation, design, and finalization of these prototypes on paper as well as all the attachments that go with them. The design drawings and dimensions were carried out by me and another student designer. We also created Adobe Photoshop renders for each helmet. I then helped with hand carving the three high-density 20 lbs. REN foam models.

SKEtches

photoshop drawings

Photos

reflection

This was my first taste of real world industrial design experience and it was incredible. I faced deadlines that encroached all but too slow. I got to design several products that have a chance at being manufactured. I presented our research and designs to the CEO and his best representatives of a billion dollar company! From research to ideation to prototyping, I was there for it all and helped on a majority of every step of this elaborate process.

During this process we faced challenges besides the short time frame we had. Our concepts presented to Clayco at midterms weren’t exactly what they had in mind so we had to regroup. This was new for me because for the first time I wasn’t just making my designs. I was designing for someone. The research we did was for a legitimate goal: To create a modern design that was safe, comfortable, and lightweight. I was designing for everyone else. I was designing not just for the company but also construction workers and their families.

Below is a link to the full 200 page process book for this project.